Bspkl.A GNS Science green hydrogen venture

GNS Science’s first spin-out company, Bspkl, represents an exciting step towards a zero-carbon future, meaningfully powered by green hydrogen.

Powered by GNS' hydrogen expertise

GNS Science is delivering research and technology solutions that will play a major role in enabling New Zealand’s transition to a carbon-zero future.

Our green hydrogen programme is striving to make green hydrogen affordable and more widely adopted as a viable energy carrier and fuel. It is delivering research and innovation that has significant commercial potential. We’re collaborating with industry and research partners to ensure that GNS’ world-class expertise and innovation is accessible, impactful, and able to be applied as real-world solutions.

Meet Bspkl.

Bspkl is a new stand-alone commercial entity out of GNS Science, brought to life thanks to 2.5 million dollars of funding from WNT Ventures and the WNT group, Investible, and other investors.

Bspkl technology is set support the transition to a sustainable and low-carbon future through their innovative approach to manufacturing Catalyst Coated Membrane (CCM) for hydrogen electrolysers, helping to accelerate hydrogen’s widespread adoption as a clean energy source.

GNS Science is a 10% shareholder in Bspkl and will continue to assist with research and collaboration as they bring their technology to market.

The Bspkl technology

At the heart of Bspkl’s innovation is a Catalyst Coated Membrane (CCM) invented by Jérôme Leveneur, GNS Ion Beam Materials Scientist and Chief Technical Officer of Bspkl.

The CCM significantly reduced the amount of platinum and iridium (one of the rarest naturally occurring elements) required to manufacture Proton-Exchange Membrane (PEM) electrolysers. The Bspkl CCM not only requires 25 times less platinum and iridium than traditional options but is also production ready at small commercial scale.

Following their successful seed funding round, Bspkl will now enter a testing phase in preparation to bring their technology to market.

Why green hydrogen?

Hydrogen is a highly flexible energy carrier that can be used in transport, electricity generation, and to power a range of industrial processes. However, 95% of hydrogen produced globally is ‘brown hydrogen’, produced from coal and natural gas, and it is responsible for CO2 emissions.

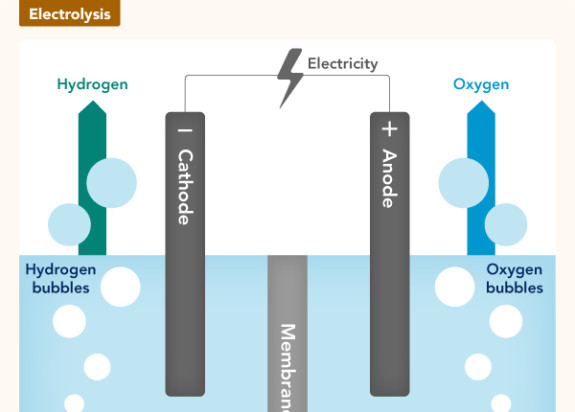

Green hydrogen, produced by splitting water into hydrogen and oxygen using electrolysis from renewable energy sources, is carbon neutral. But, in the current global context of supply chain issues, rising costs, and shortages of raw minerals, its affordability and availability faces a number of challenges.

Bspkl is an exciting step towards addressing these challenges, and unlocking a zero-carbon future, meaningfully powered by green hydrogen.