Carbon re-injection revealed to be a win-win-win!

Geothermal power stations are increasingly re-injecting their carbon emissions to combat their carbon tax and climate impact.

But the long-term impact of re-injection is still relatively unknown, so we conducted a series of experiments, and found a triple-winning solution.

Carbon-neutral power

New Zealand’s commitment to a low-carbon future is a significant challenge. We need to ensure an affordable, secure, and sustainable supply of energy while facing a rapidly changing climate.

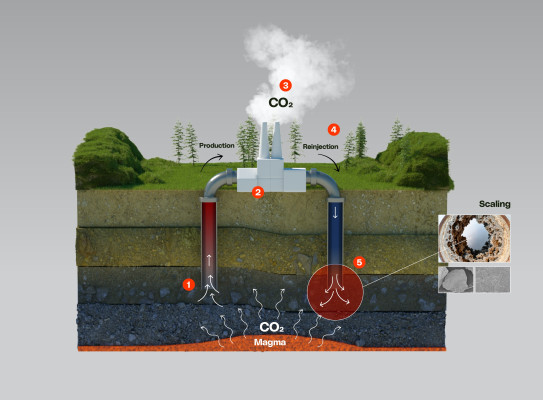

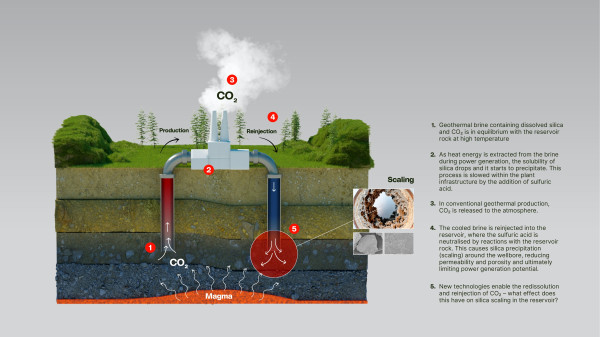

The nation’s geothermal power stations make a significant and increasing contribution to baseload electricity generation, but the naturally occurring carbon dioxide dissolved in geothermal fluid is emitted as part of the current generation process.

This means geothermal electricity generation is not free from carbon emissions and the cost of carbon tax.

Experimental injection

Worldwide, geothermal electricity producers are shifting towards re-injecting CO₂ back into the reservoir by mixing it with the expended geothermal brine. This process, called co-injection, can thereby transition geothermal generators from CO₂ emitters to CO₂ neutral.

However, the long-term impact of CO₂ co-injection on the performance of the geothermal reservoir remains unknown. To understand how it may impact the continued performance and sustainability of the reservoir, we developed a new experimental method to test the wider effects of co-injection.

A foul problem

Mineral scaling is another ongoing challenge for power plant operators. Amorphous silica is the most prevalent scaling mineral, forming along the flow path in the production pipes and wells, and the subsurface reservoir itself.

To mitigate and slow the rate of silica precipitation, acid is injected into the geothermal brine. However, when this acidified fluid is re-injected into the subsurface, it reacts with the surrounding rock minerals. This reaction neutralises the acid and triggers rapid silica precipitation.

This process can lead to the fouling of rock close to the re-injection wells, necessitating the drilling of new wells, thereby significantly increasing operational costs.

Our research and results

Our experiments were based on the concept that re-injected CO₂ forms carbonic acid when dissolved. This, in turn, makes the combined re-injected brine more acidic, and therefore prevents silica scaling.

With our novel dual-stage autoclave method, we simulated the interaction CO₂-charged geothermal brine and the reservoir rock.

- Our control experiment with greywacke (a major reservoir rock type in the Taupō Volcanic Zone) led to moderate silica scaling.

- In the second experiment, calcite was added and it produced consistently higher scaling, thus supporting the hypothesis that calcite in the re-injection rock causes enhanced silica scaling.

- In a third experiment, using greywacke and calcite, 2000 mg of CO₂ per kg of brine were added to investigate the effect of CO₂ co-injection.

Silica scaling in this third experiment was nearly zero, proving the concept that CO₂ co-injection can mitigate this ongoing challenge for geothermal power operators.

CO₂ acts as a natural cleaning agent

The tests also revealed an important side effect of co-injecting high concentrations of CO₂, the accelerated removal of calcite from the rock. This means that the CO₂ is acting as a “cleaning agent” to remove the cause of rapid silica scaling.

So as a win-win-win solution, the co-injection of captured CO₂ with the expended geothermal brine can,

- lower the emissions, therefore the carbon tax, for geothermal operators

- make the expended geothermal brine that flows into the subsurface retain its acidity, which slows silica scaling in the rock

- at high concentrations, accelerate the removal of calcite from the rock, meaning that the CO₂ is acting as a “cleaning agent” because it removes the cause of silica scaling.

By using CO₂ as a silica anti-scalant, power generators can mitigate significant long-term costs. Co-injection can eliminate carbon emissions and the payment of carbon tax, while at the same time improving the efficiency of production operations and the sustainability of the geothermal reservoir.

Our funding and forward direction

Site-specific studies were funded by both domestic and international geothermal operators, and have led to the formulation of the novel concept of CO₂ as a silica anti-scalant. Our research was supported by the Strategic Science Investment Fund (SSIF) Programmes Contract C05X1702 granted to GNS by the Ministry of Business, Innovation and Employment (MBIE).

Encouraged by the promising results, two New Zealand geothermal power generators have requested further experimentation. The goal is to further explore the effects of CO₂ co-injection, potentially leading to more efficient and sustainable geothermal power production.